Project Details

Scope of Project

The Vapour Compression Evaporator (VCE) Fan inspection & Centrifuge inspection. Project involved several critical tasks related to the annual inspection and maintenance of various components within the manufacturing system, as well as a separate specialised inspections on a Ferrum Centrifuge.

• Cleaning of oil coolers in the VCE gearbox

• Inspection of white metal bearings

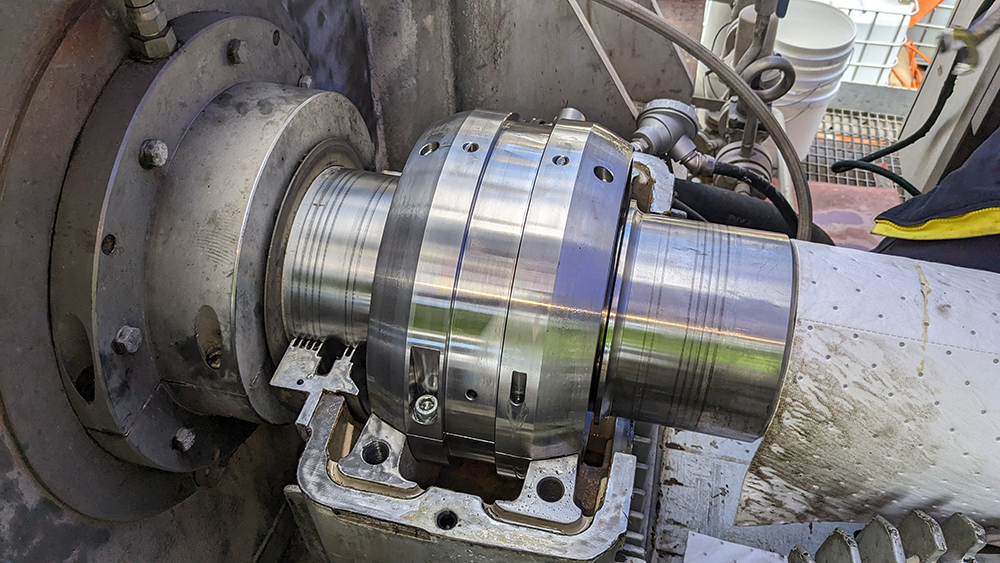

• Changing out of carbon seals

• Replacement of a damaged pressure gauges

• Replacement of the VCE Fan Drive Motor

• Centrifuge Inspections

• Inspections and repairs to LP Bearing Shaft Earthing Brushes

Key Deliverables

We provided effective project management and execution capabilities, ensuring the project completion was on time and met our client’s safety, quality and assurance expectations.

Proficiencies in our procedures and resource utilization resulted in works being completed with the allocated budget, showcasing financial responsibility and project management acumen.

We successfully implemented the use of high torque tools and laser alignment technology, enhancing precision and efficiency in specific tasks to overcome challenges and achieve the project’s objectives successfully.

Achievement of zero Lost Time Incidents (LTI’s), showcasing our team’s commitment to safety and reinforcing a positive safety culture within the team.